CUSTOMIZED SUSPENSION LOWERING

Fulfills Every Wish

KW coilover suspensions, KW coilover springs, and KW DLC AirSuspensions allow the suspension to be steplessly lowered within the framework of the certified technical component report. For example, our Street Comfort products allow for a customized height setting with gentle suspension lowering from 10 - 50 mm, while the Street Performance products allow the maximum technically possible suspension lowering range from 45 - 85 mm, depending on the vehicle. This means that the suspension can be lowered to suit the personal needs of the user and, depending on the product category, a setting ranging from Comfort to Performance can be chosen.

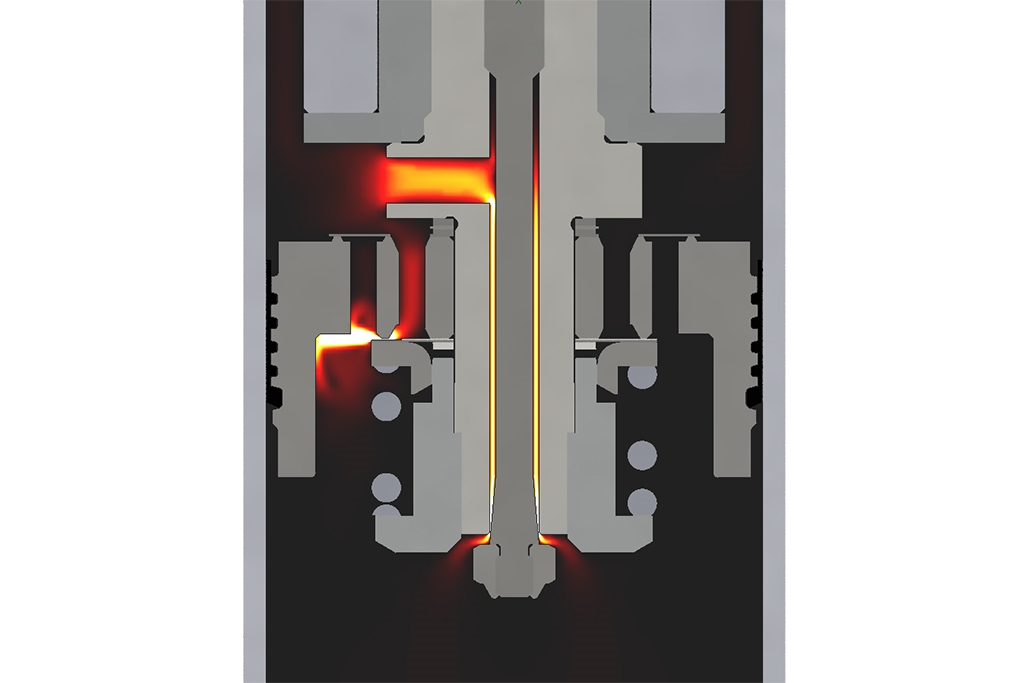

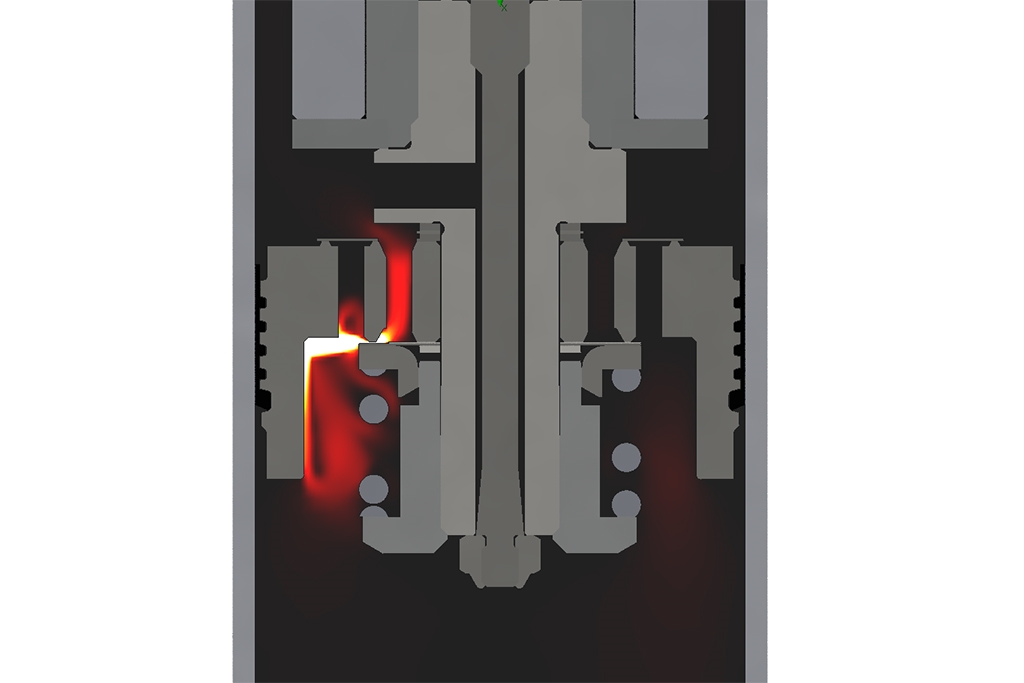

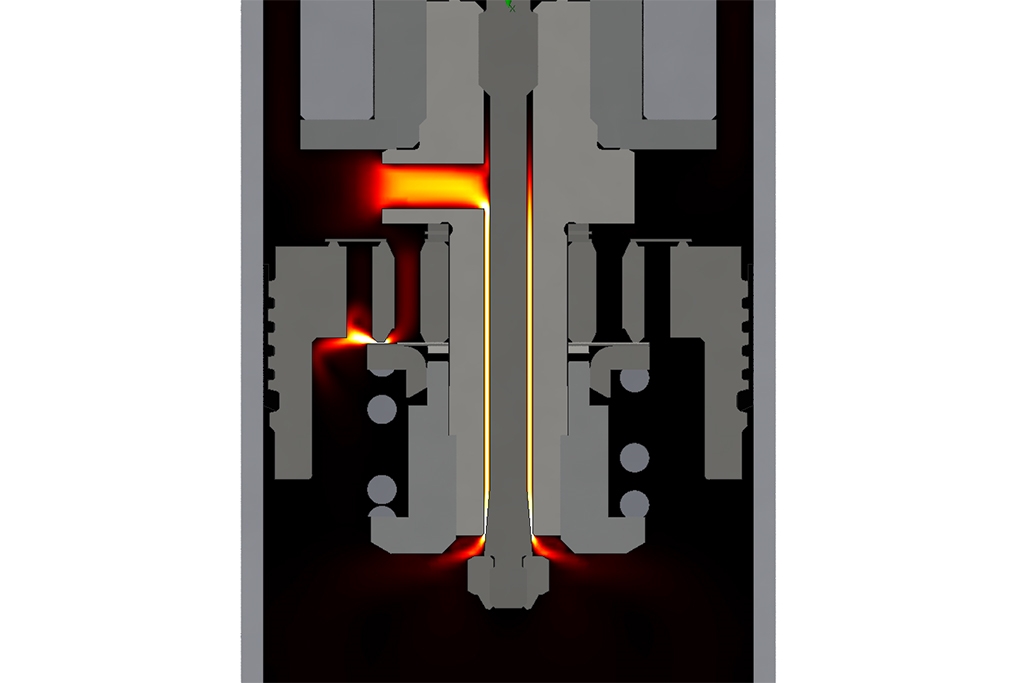

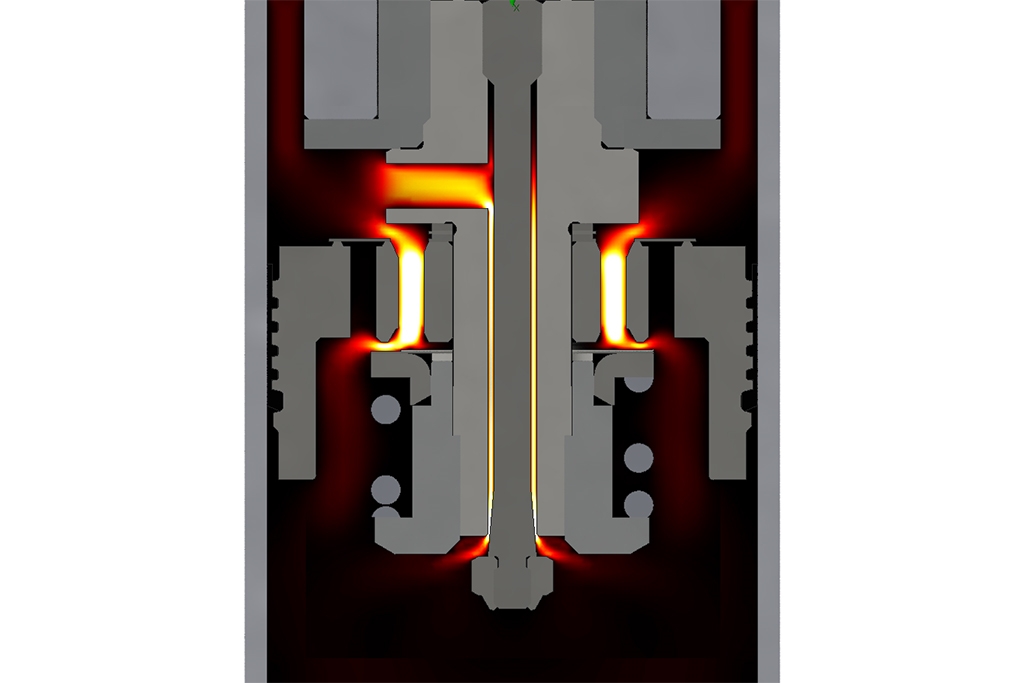

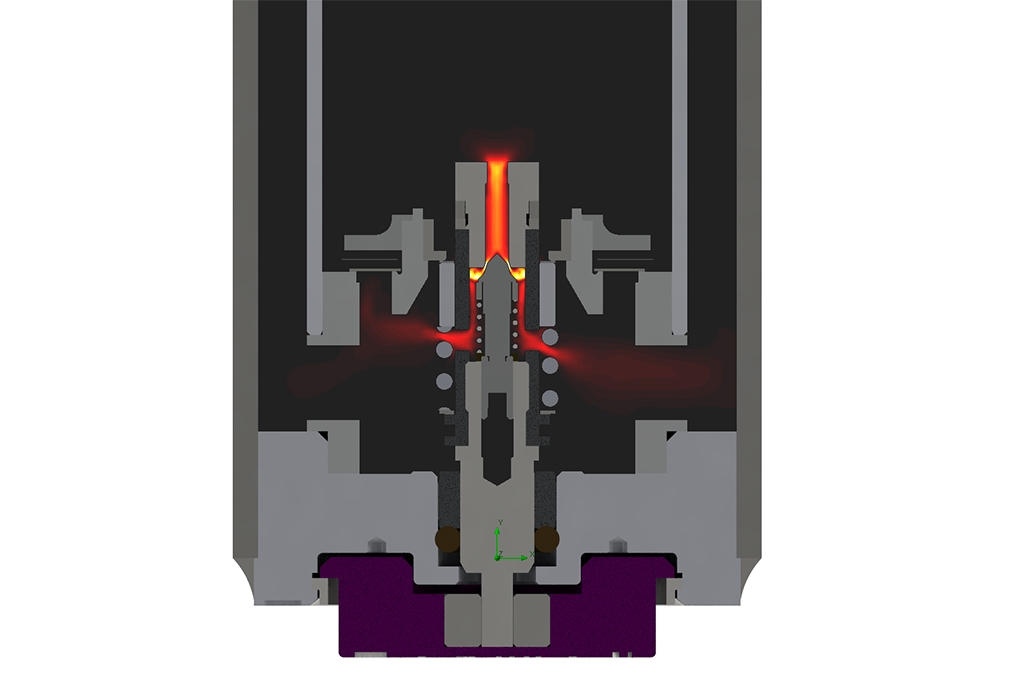

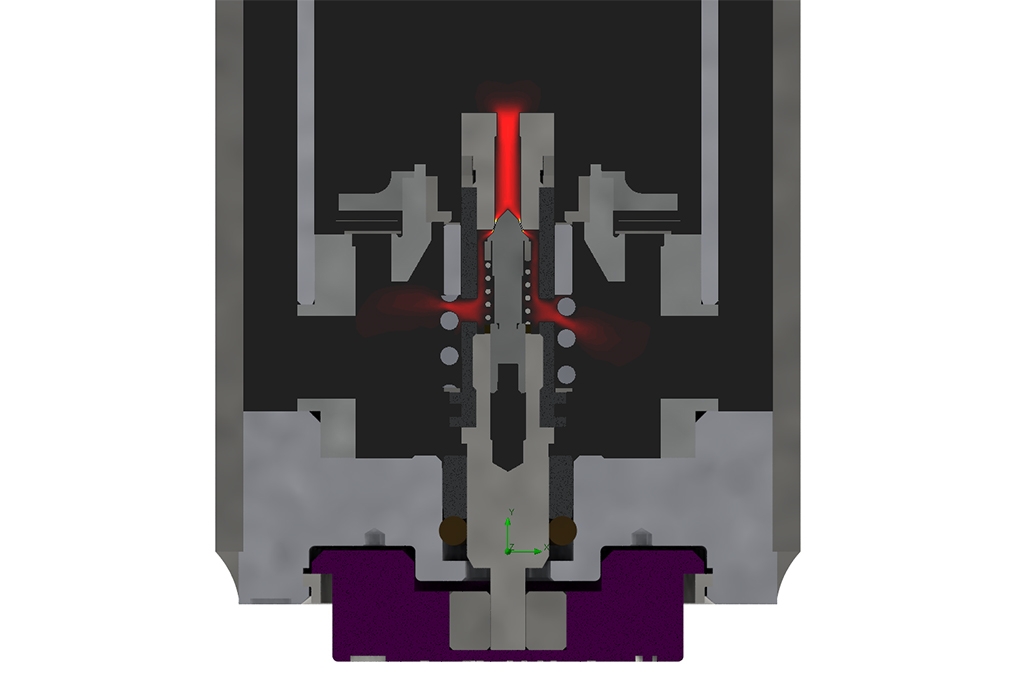

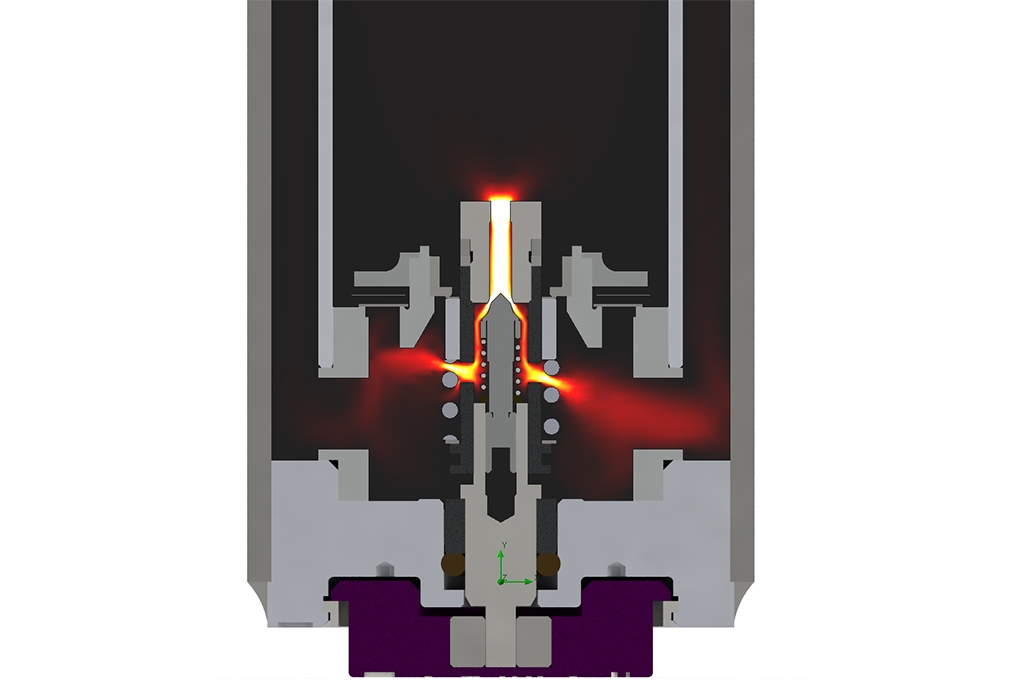

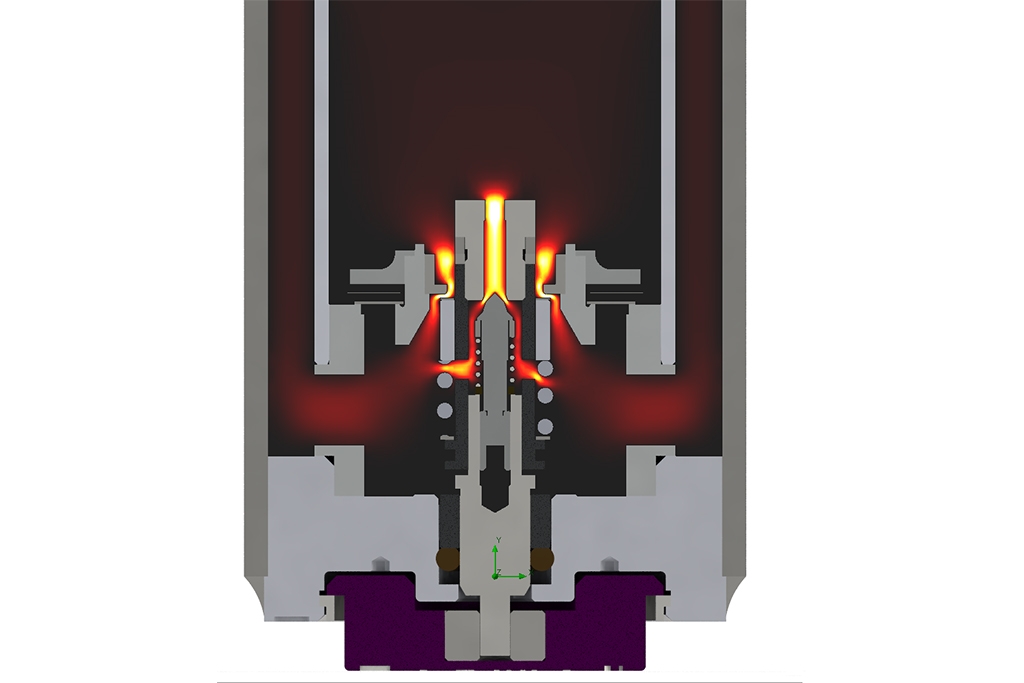

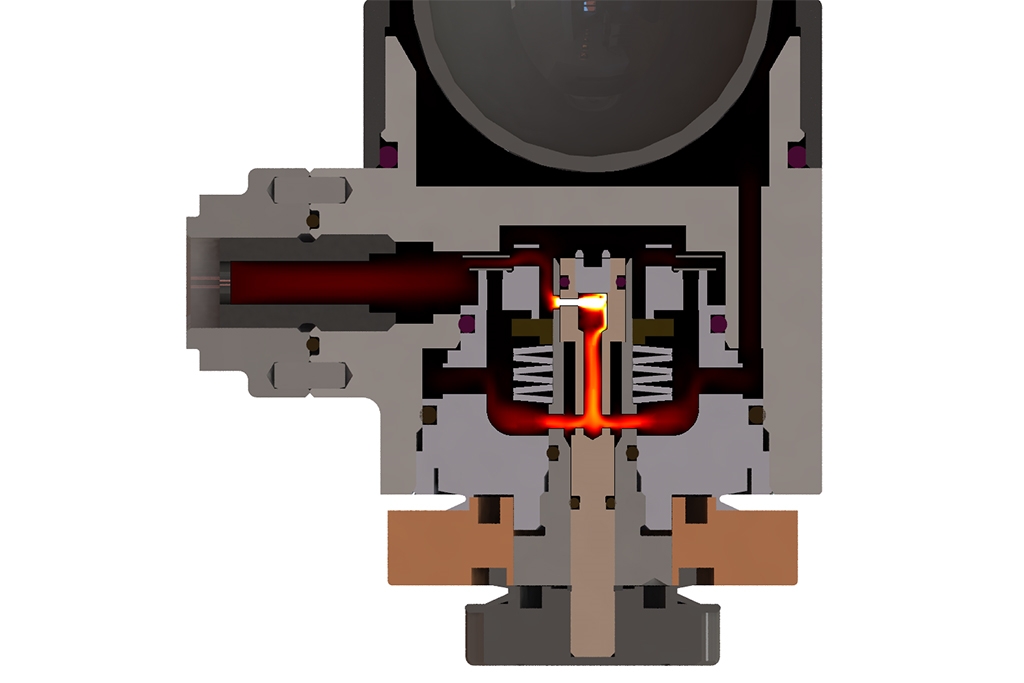

Compression (Low)

Compression (Low) Rebound stage

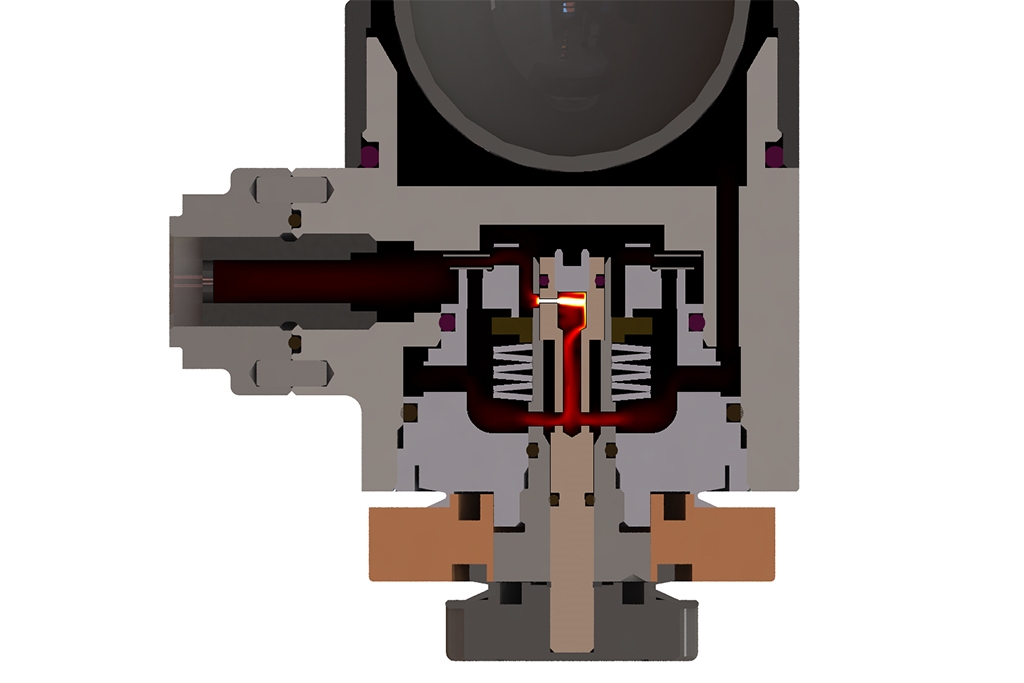

Rebound stage Compression stage

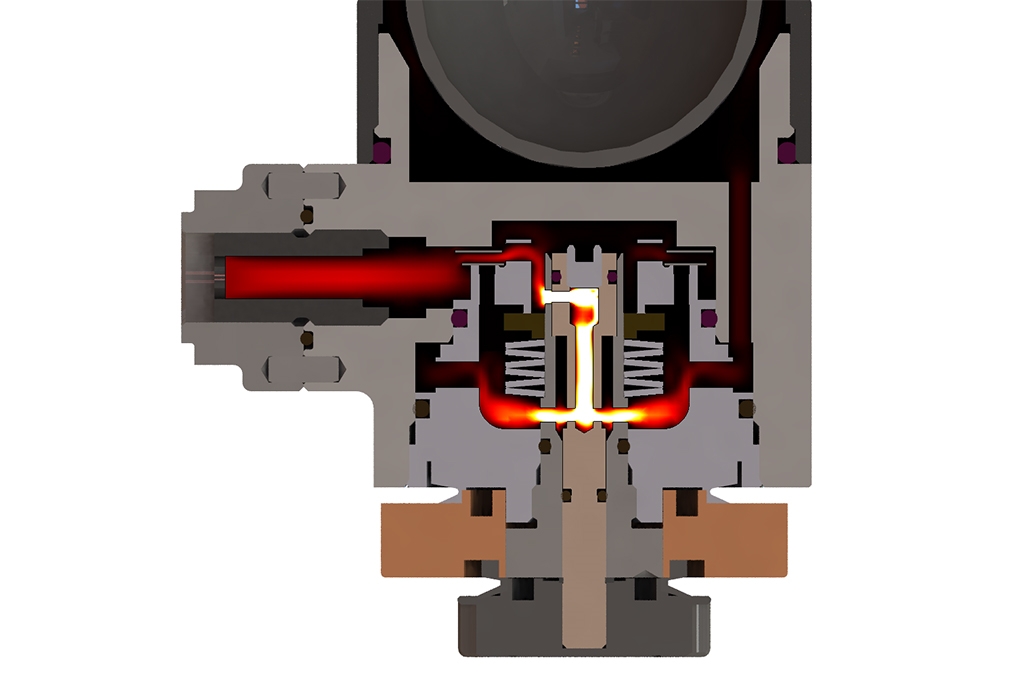

Compression stage Compression stage

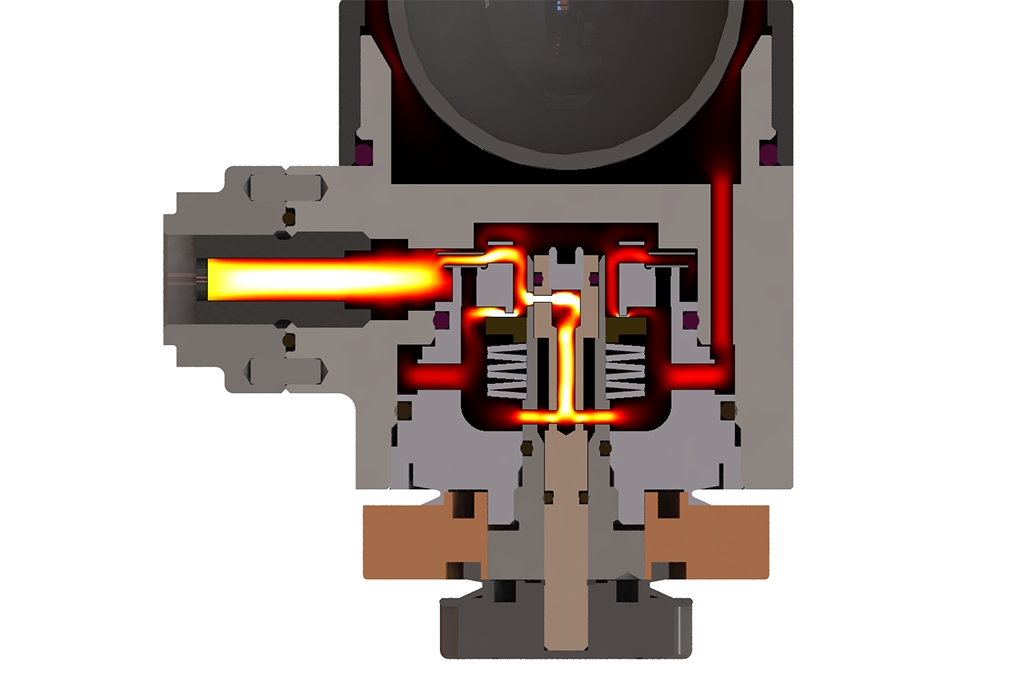

Compression stage Compression (Low- & Highspeed)

Compression (Low- & Highspeed)